Empowering the energy sector to hire safer, smarter, and stronger workforces—backed by data.

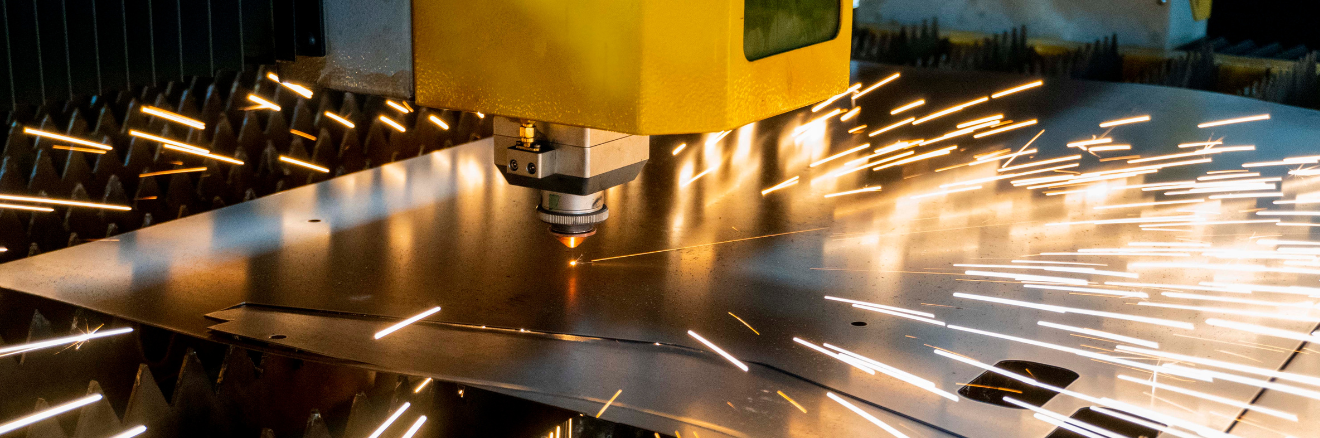

Manufacturing

Psychometric assessments and recruitment tools for the Manufacturing industry.

From the production line to the engineering desk, manufacturing roles demand a mix of precision, reliability, and safety-first thinking. As automation accelerates and skill gaps widen, hiring the right people has never been more critical.

Testgrid’s assessment solutions help manufacturers identify high-performing, safety-conscious candidates across production, technical trades, engineering, and quality control. Whether you’re scaling up operations or improving retention, our data-driven tools support better hiring decisions—reducing risk, boosting productivity, and building a workforce fit for the future of Australian manufacturing..

70%

Manufacturing employers say roles

are hard to fill due to skill shortages

373,300

Average annual non‑fatal

manufacturing injuries

Production & Operations

- Production Manager

- Operations Manager

- Plant Operator

- Manufacturing Supervisor

- Shift Supervisor

- Production Scheduler

- Inventory Controller

- Warehouse Supervisor

- Dispatch Coordinator

- Control Room Operator

Skilled Trades & Technical Operations

- Machine Operator

- CNC Operator

- Welder

- Boilermaker

- Fitter & Turner

- Fabricator

- Assembler

- Process Worker

- Maintenance Technician

- Machinist

- Forklift Driver

- Packaging Operator

- Toolmaker

- Food Process Worker

- Injection Moulding Technician

Engineering and Design

- Manufacturing Engineer

- Mechanical Engineer

- Electrical Engineer

- Mechatronics Engineer

- Industrial Engineer

- Automation Engineer

- Electronics Technician

- CAD Designer/Drafter

- R&D Engineer

- Engineering Technician

Quality and Compliance

- Quality Assurance Officer

- Quality Control Inspector

- Compliance Coordinator

- WHS (Work Health & Safety) Officer

- ISO Auditor

- Test & Inspection Technician

- Documentation & Compliance Analyst

- Production Tester

- Environmental Compliance Officer

Why and Where to use Testgrid

Safety Focus

- Identifies candidates with strong safety awareness to reduce accidents

Role Fit

- Matches skills to job needs, lowering turnover

Higher Output

- Ensures aptitude for precision work, boosting efficiency

57% of on-site accidents are human errors

Screen out unsafe employees and reduce time lost to injury.

A limited talent pool with younger generations favouring other industries – a company working with current technology and assessments is more attractive to a younger generation.

Hiring For?

- Entry-Level and Operational Roles

- Skilled Trades & Technical Operations

- Professional and Technical Specialists

- Executive and Senior Management

“Working with Testgrid made our apprentice recruitment process so much smoother and more effective.”

– Energy Queensland

RESULTS

Reduction in failure rate

Completion rate

Retention rate

Eliminated 30% failure rate

“Testgrid’s assessments have transformed the way we hire”

– Mining Company

RESULTS

Reduction in Time Lost to Injury

Reduction in Occupational Diseases (OD)

Reduction in Total Recordable Injury (TRI)

In 2 Decades

Enable faster and smarter hiring decisions. Take the first step to streamlining your recruitment process.

TESTGRID CAN HELP TO

35%

Reduction time to shortlist

29%

Increase in sales performance

20%

Reduction in staff turnover

80%

of Fortune 500 companies use psychometric assessments

Request a consult

Our Publishing Partners